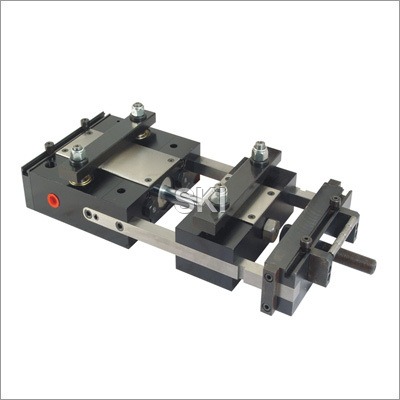

Double Pulling Cylinder Pneumatic Feeder

Double Pulling Cylinder Pneumatic Feeder Specification

- Power

- Pneumatic (compressed air)

- Media

- Clean, dry compressed air

- Structure

- Double Cylinder with Synchronized Pulling Mechanism

- Material

- Stainless Steel and Aluminium

- Air Consumption

- 2.5 L/cycle (approx.)

- Speed

- Adjustable, up to 150 cycles per minute

- Maximum Torque

- 150 Nm

Double Pulling Cylinder Pneumatic Feeder Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 1 Week

About Double Pulling Cylinder Pneumatic Feeder

We bring forth for our clients an extensive collection of high quality Pulling Cylinder Pneumatic Feeder that is highly demanded in the market for its high production capacity. Also, this air feeder can be customized as per the patrons diverse requirements. It is widely used in hydraulic and pneumatic industry. Under the stern observation of our adroit team of professionals, the offered air feeder is manufactured in line with the set industry standards. Furthermore, our precious clients can avail this Pulling Cylinder Pneumatic Feeder at nominal price range.

Features:

-

Low maintenance

-

High performance

-

Longer working life

-

Strong construction

Efficient Synchronized Pulling Mechanism

Designed with a double-cylinder structure and synchronized pulling, this pneumatic feeder ensures smooth, consistent material movement. The high torque and adjustable cycling speed make it adaptable to different processing demands, resulting in enhanced production efficiency and reduced downtime in industrial environments.

Robust Material Construction

Fabricated from corrosion-resistant stainless steel and lightweight aluminium, the feeder offers excellent durability and minimal maintenance requirements. This construction not only extends the machines lifespan but also maintains optimal performance, particularly in challenging operational settings.

FAQs of Double Pulling Cylinder Pneumatic Feeder:

Q: How does the double pulling cylinder pneumatic feeder operate?

A: The feeder utilizes a double-cylinder system with a synchronized pulling mechanism, powered by compressed air. This design enables precise material feeding at speeds adjustable up to 150 cycles per minute, ensuring consistent and reliable operation in automated setups.Q: What types of industries benefit most from this feeder?

A: Industries involved in automated assembly, stamping, packaging, and material handling benefit greatly from this feeder, especially where high speed, precision, and durability are essential.Q: When should I choose a double pulling mechanism over a single cylinder feeder?

A: A double pulling mechanism should be selected when enhanced synchronization, greater torque, and more stable material handling are required, particularly for high-volume or high-speed production lines.Q: Where should the feeder be installed for optimal results?

A: The pneumatic feeder should be set up within automated production lines where clean, dry compressed air supply is available. Its robust structure allows flexible installation in various industrial environments across India.Q: What is the recommended process for maintaining this pneumatic feeder?

A: Regularly check and clean all air filters to ensure only clean, dry air is supplied. Inspect cylinder seals, lubricate moving parts as needed, and follow the manufacturers guidelines for part replacement or servicing to ensure longevity.Q: How is the speed of the feeder adjusted during operation?

A: The feeders speed is adjustable through pneumatic flow control valves, allowing operators to fine-tune the cycling rate up to 150 cycles per minute, depending on specific material and process requirements.Q: What are the key benefits of using this pneumatic feeder?

A: The primary benefits include high feeding speeds, synchronized pulling for precise positioning, durability from stainless steel and aluminium construction, and stable operation even at maximum torquedelivering increased productivity and reduced maintenance costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pneumatic Feeder Category

Heavy Duty Pneumatic Feeder

Minimum Order Quantity : 1 Unit

Structure : Robust and Heavy Duty Construction

Maximum Torque : High Torque Output

Power : Pneumatic

Media : Compressed Air

Material : High Grade Steel

Industrial Pneumatic Feeder

Minimum Order Quantity : 1 Unit

Structure : Compact, Rigid Construction

Maximum Torque : 180 Nm

Power : Pneumatic

Media : Compressed Air

Material : Mild Steel

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry